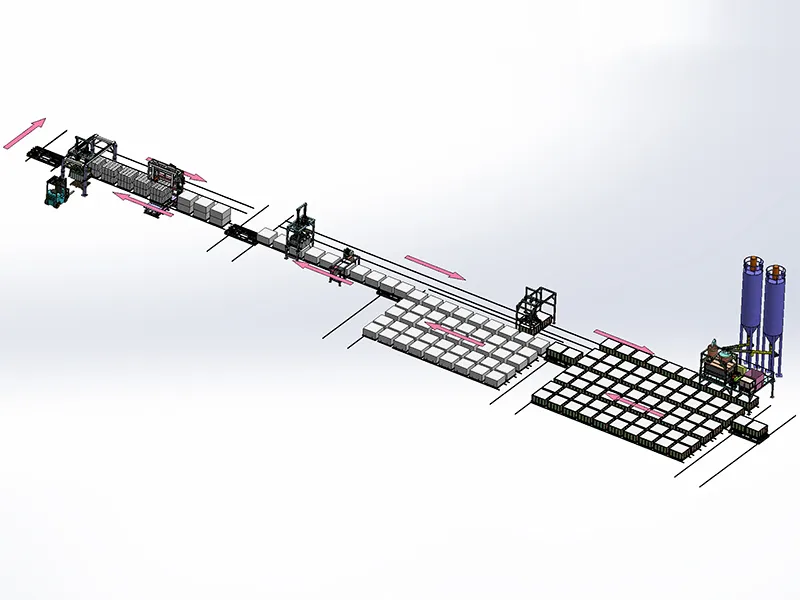

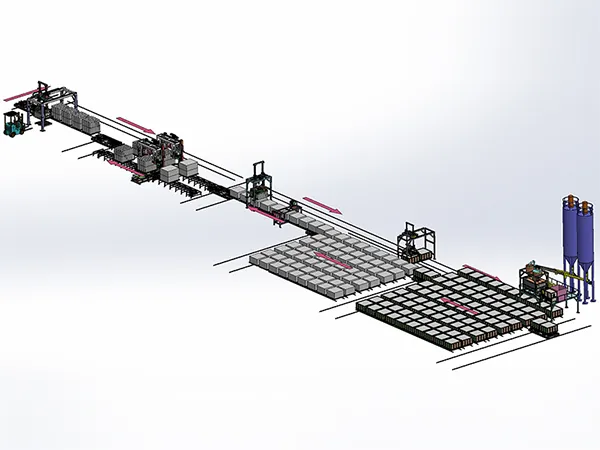

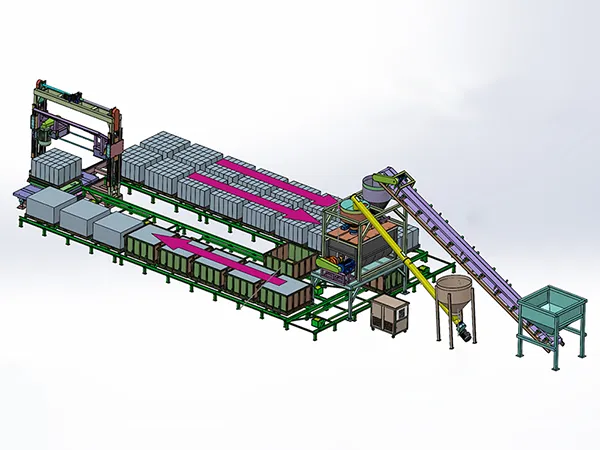

The 100m³/day lightweight concrete production line is a standard configuration with a high level of automation, ideal for small-scale block manufacturing. It includes a complete set of core equipment such as a feeding and dosing system, foam generator, automatic demoulding system, vertical cutting saw, and a stacking and packing unit. The production process is highly efficient, and the equipment is easy to operate and maintain.

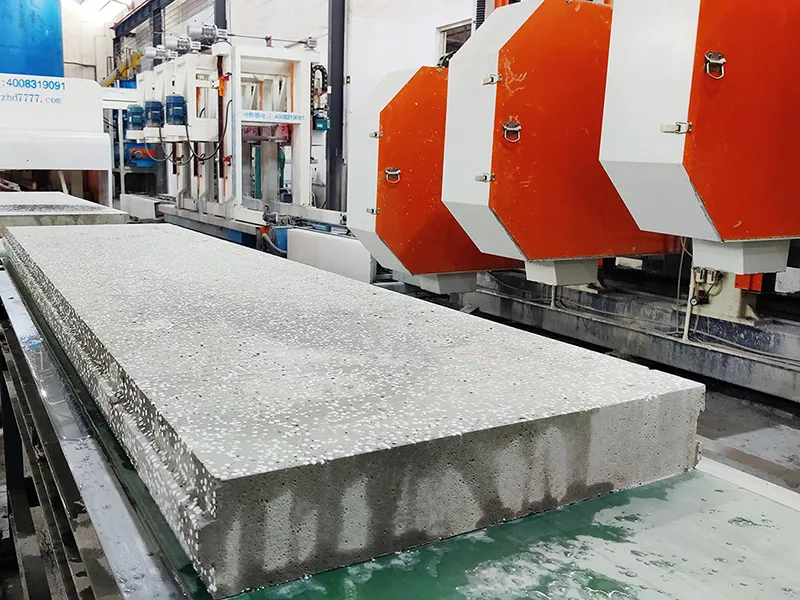

With a compact layout requiring only 800–1000 m² of space, this lightweight concrete production line can produce AAC blocks, homogeneous self-insulating blocks, and ceramsite blocks with a dimensional tolerance of just ±1mm. Only 5 to 7 operators are needed to run the full process. The system also allows for future expansion, such as adding an additional cutting unit to increase output. Contact us to configure your lightweight concrete production line for efficient, high-precision manufacturing.

-

Screw feeder

Screw feeder -

Belt conveyor

Belt conveyor -

Powder dosing and weighing system

Powder dosing and weighing system -

Water dosing system

Water dosing system -

Foam generator

Foam generator -

Screw air compressor

Screw air compressor -

Aggregates mixing & dosing station

Aggregates mixing & dosing station -

Horizontal shaft mixer

Horizontal shaft mixer -

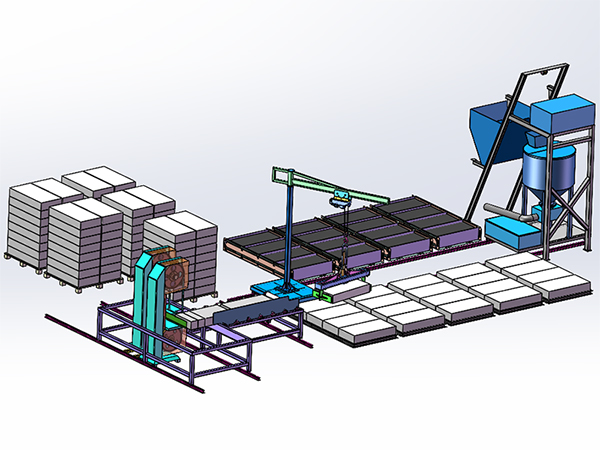

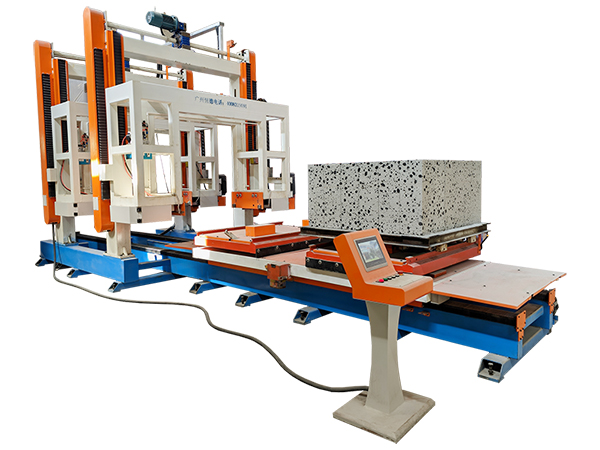

Gantry vertical cutter

Gantry vertical cutter -

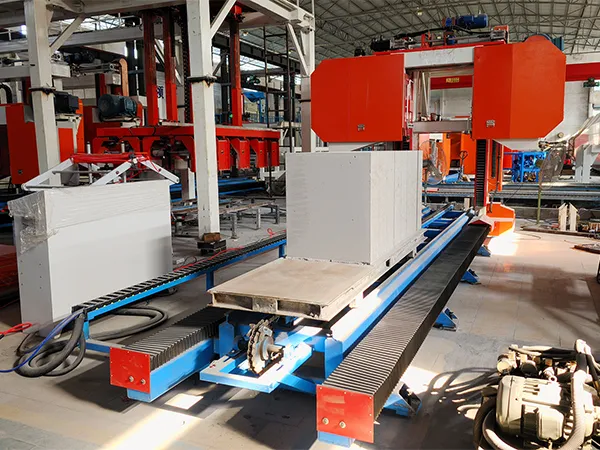

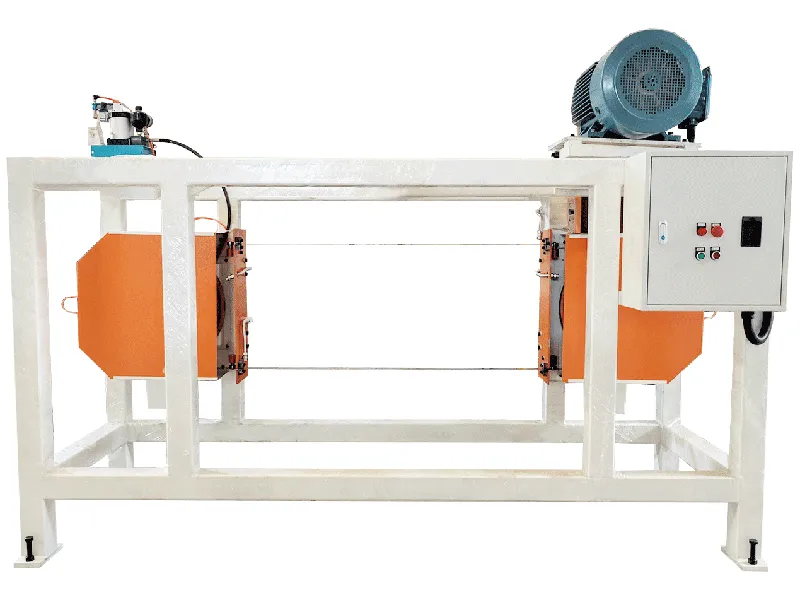

Concrete block pre-cutter

Concrete block pre-cutter -

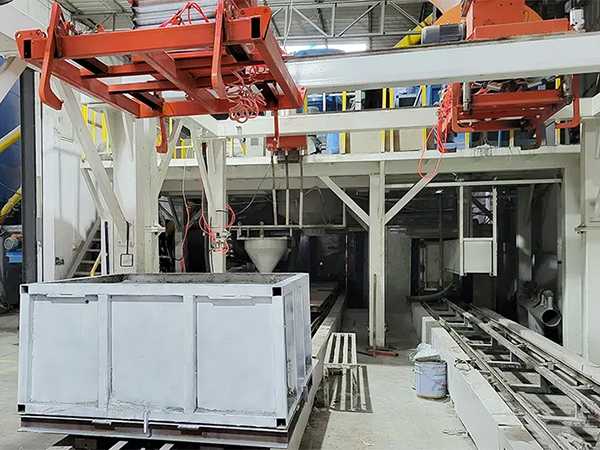

Demoulding crane

Demoulding crane -

Lifting & stacking machine

Lifting & stacking machine -

Concrete block grab / lifter

Concrete block grab / lifter -

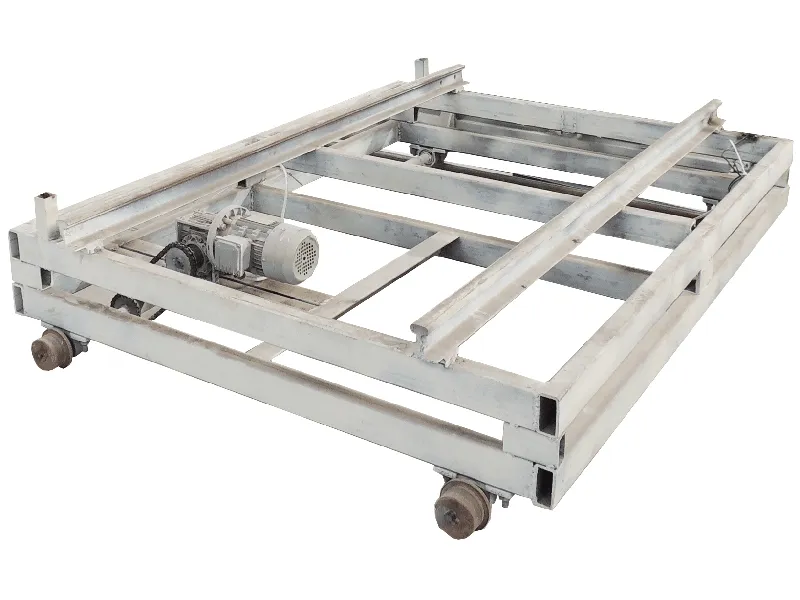

Transfer cart

Transfer cart -

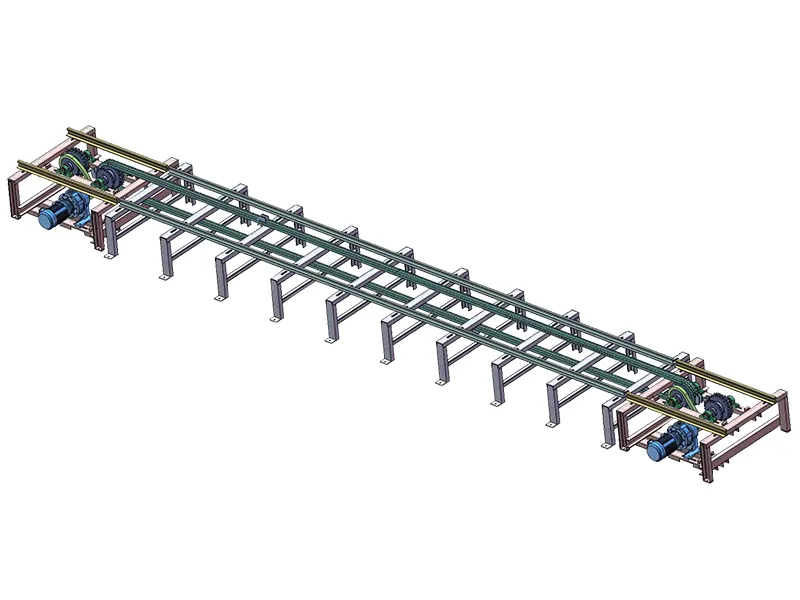

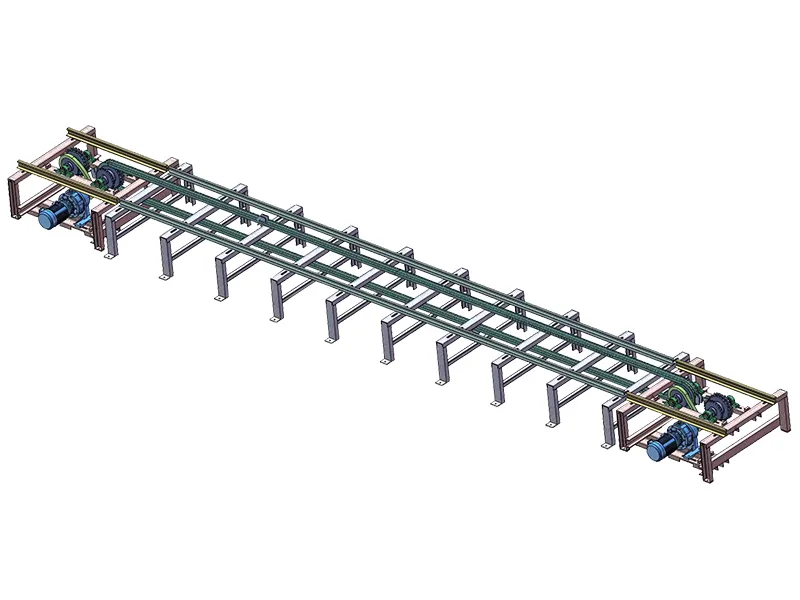

Automatic feeding & discharging line

Automatic feeding & discharging line -

PLC control console

PLC control console -

Foam generator control panel

Foam generator control panel -

Remote control module

Remote control module -

Concrete block mould

Concrete block mould -

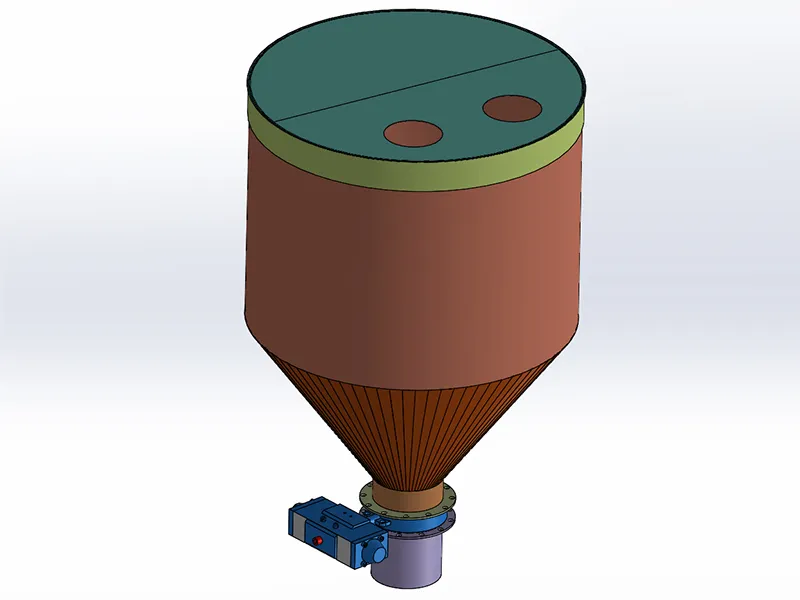

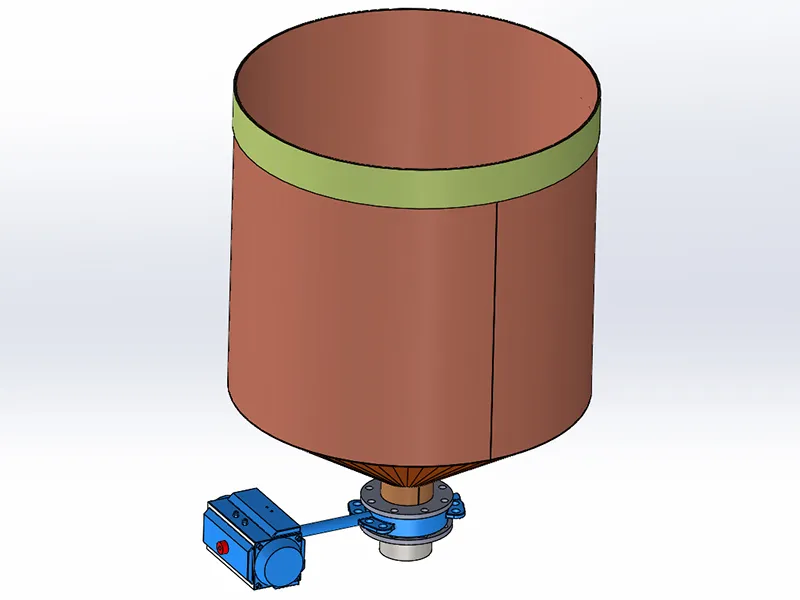

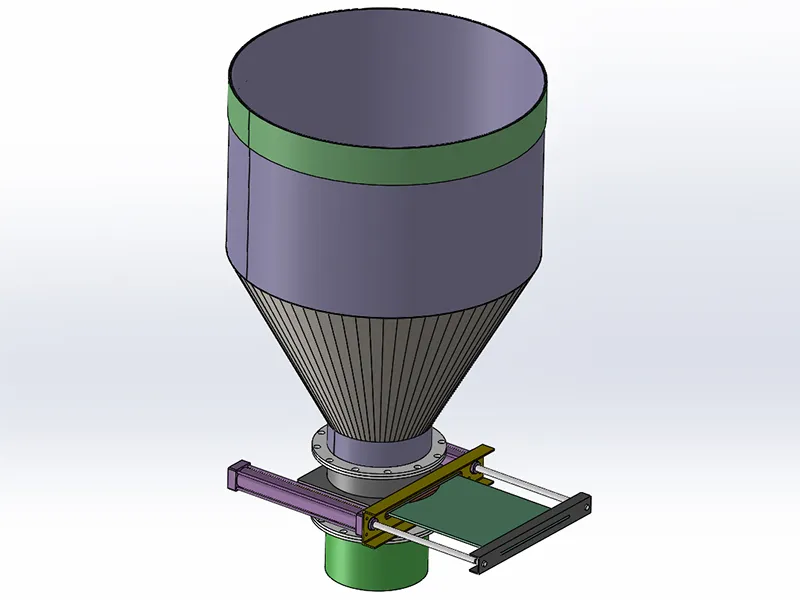

Dosing hopper

Dosing hopper -

Demoulding, mould return and pouring line

Demoulding, mould return and pouring line

| Configuration | Model | Dimensions (mm) | Power per unit (kW) | Total power (kW) | Quantity of machine |

| Screw feeder | HDSL | 8000×350×1100 | 11 | 22 | 2 |

| Belt conveyor | HDPDA | 9000×800×800 | 2.2 | 2.2 | 1 |

| Powder dosing and weighing system | HDFL | D1310×H1950 | 0.55 | 0.55 | 1 |

| Dosing hopper | HDSS | D1000×1500 | 0.55 | 0.55 | 1 |

| Water dosing system | HDSL | D1100×H1140 | 0.55 | 0.55 | 1 |

| Foam generator | HDKWF1 | 1150×750×1140 | 7.5 | 7.5 | 1 |

| Screw air compressor | HDKY | L1500×W500×H2000 (air storage tank 0.8m³×1) | 15 | 15 | 1 |

| Aggregates mixing & dosing station | 6000×6400×2600 | 1 | |||

| Horizontal shaft mixer | EPSA | 2000×1200×1200 | 22 | 22 | 1 |

| Gantry vertical cutter | HDSHM01 | 4350×3300×3650 (equipped with high-precision rotary cutting capability) | 11.1 | 11.1 | 1 |

| Concrete block pre-cutter | HDOSD1 | 3000×1000×2100 (supplied with power cable) | 22 | 22 | 1 |

| Demoulding crane | HDAS | 3700×1600×3700 | 3.2 | 3.2 | 1 |

| Lifting & stacking machine | HDDB | 4800×2900×4700 | 11.5 | 11.5 | 1 |

| Concrete block grab / lifter | HDYUK | 2200×1200×4200 | 7.5 | 7.5 | 1 |

| Transfer cart | HDBD2 | 1800×1080×400 | 3 | 15 | 5 |

| Demoulding line | HDZD | 6000×1080×470 | 2.2 | 2.2 | 1 |

| Mould return line | HDZD | 6000×1080×470 | 1.5 | 1.5 | 1 |

| Mould pouring line | HDZD | 6000×1080×470 | 1.5 | 1.5 | 1 |

| Automatic feeding line | HDZD | 4000×1100 | 0.3 | 0.3 | 1 |

| PLC control console | HDKZ1 | 1300×1100×400 | 1 | ||

| Foam generator control panel | HDCBD1 | 700×500×400 | 1 | ||

| Remote control module (enables data import and remote control functionality) | HDYC-001 | 200×150×60 | 1 | ||

| Concrete block mould | HDCM1 | 1220×1220×630 (whole set) | 1 |

- Extensive project experience: our company has undertaken over a hundred construction projects both domestically and internationally.

- Leading technological advantage: we established technical collaborations with German LUCA, German KENA, British CDS, and British TAMCK.

- Comprehensive solutions: We integrate research and development, design, production, and sales to offer turnkey solutions.

- Largest wall panel cutting system: We have developed the world's largest wall panel cutting system, capable of cutting 6-8 cubic meters in a single operation.