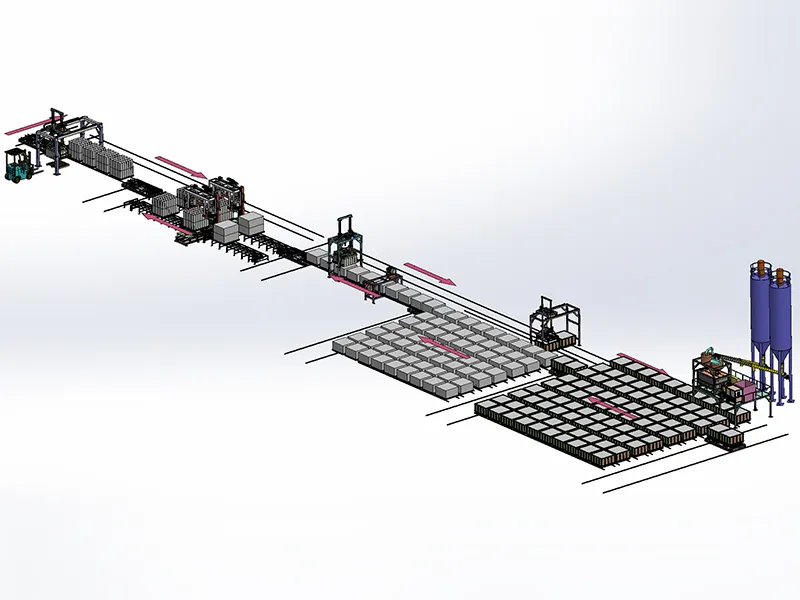

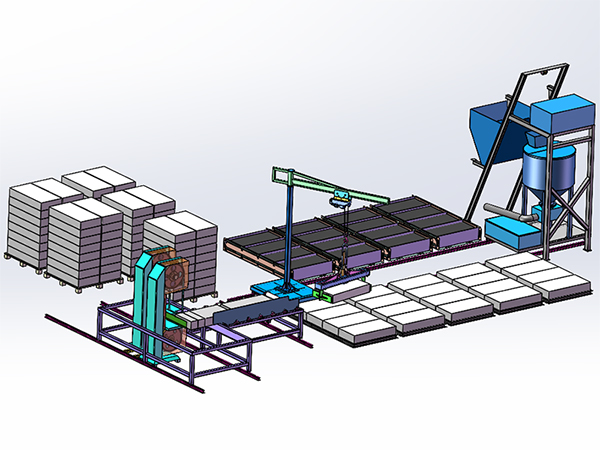

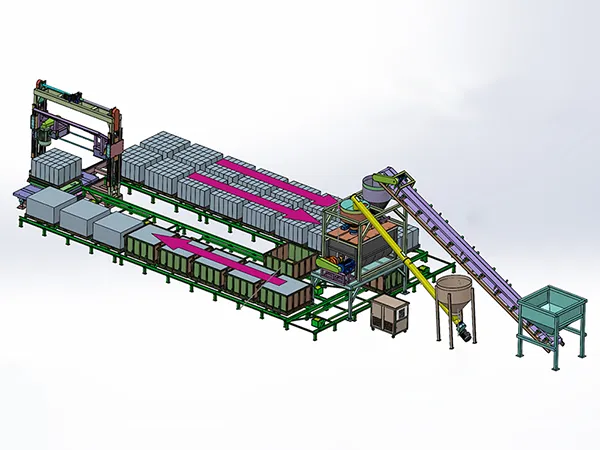

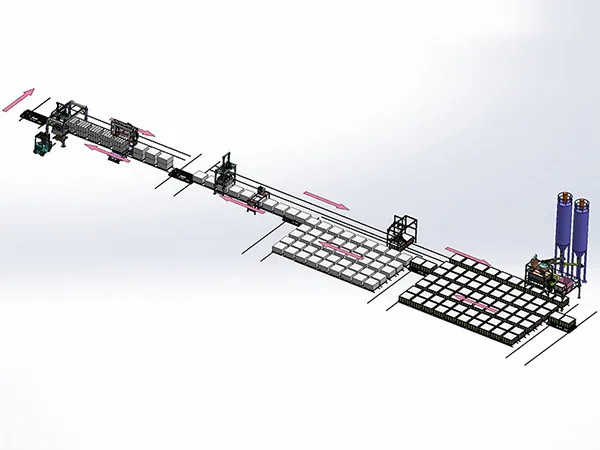

The 200m³/day lightweight concrete production line is a standard solution tailored to meet the needs of small to medium-sized building material enterprises. The system includes essential equipment such as a feeding and dosing system, foam mixing unit, automatic demoulding device, and a double-track gantry vertical cutting machine. It is easy to operate and maintain, with only 8 operators required to manage the full production cycle.

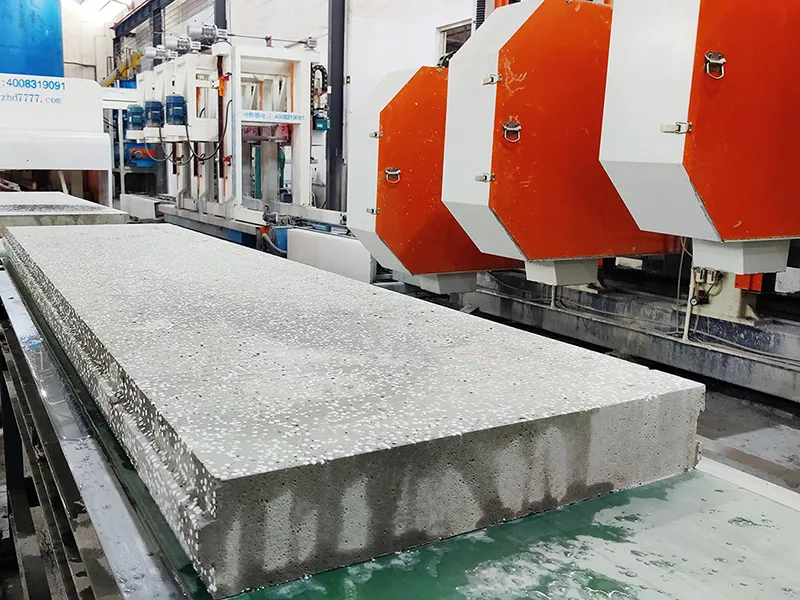

Capable of producing AAC blocks, homogeneous self-insulating blocks, and ceramsite blocks, this lightweight concrete production line delivers products with high dimensional precision—within ±1mm tolerance. With a footprint of approximately 5 mu and workshop space of 1500–1800 m², it offers an efficient layout for scaled manufacturing. The system can also be expanded with additional cutting equipment to further boost capacity. Contact us today to plan your lightweight concrete production line for reliable and scalable block production.

-

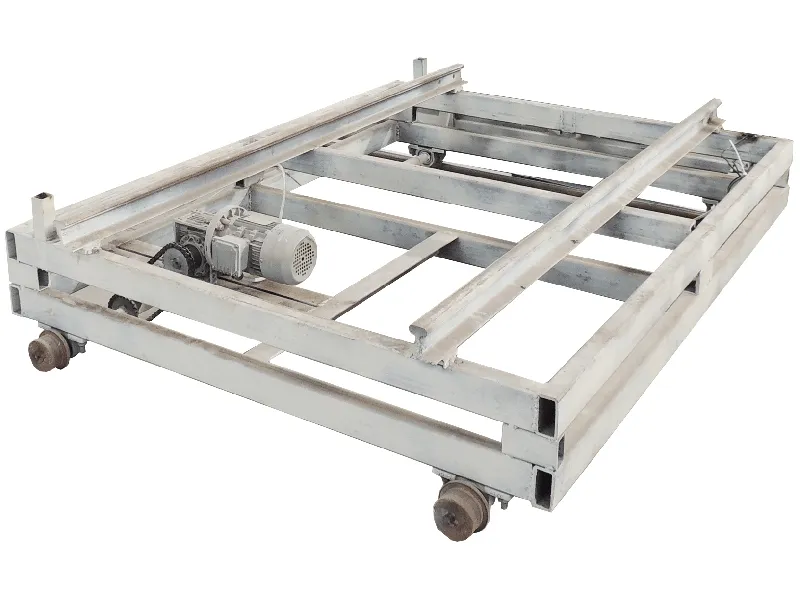

Transfer cart

Transfer cart -

Aggregates mixing & dosing station

Aggregates mixing & dosing station -

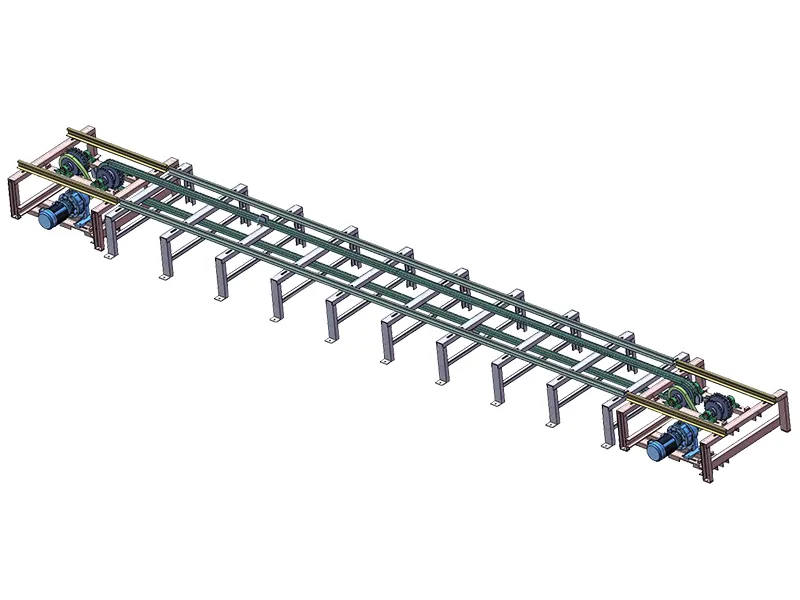

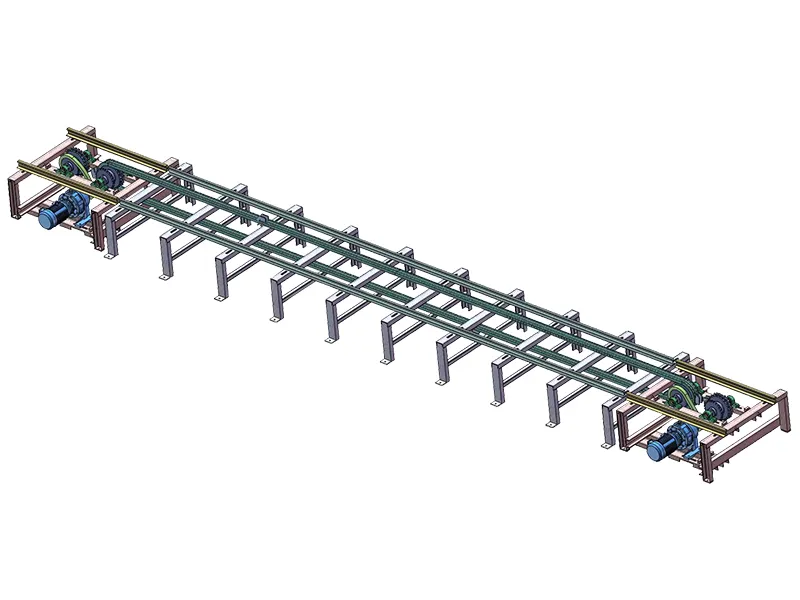

Automatic feeding & discharging line

Automatic feeding & discharging line -

Lifting & stacking machine

Lifting & stacking machine -

Foam generator control panel

Foam generator control panel -

Powder dosing and weighing system

Powder dosing and weighing system -

Demoulding, mould return and pouring line

Demoulding, mould return and pouring line -

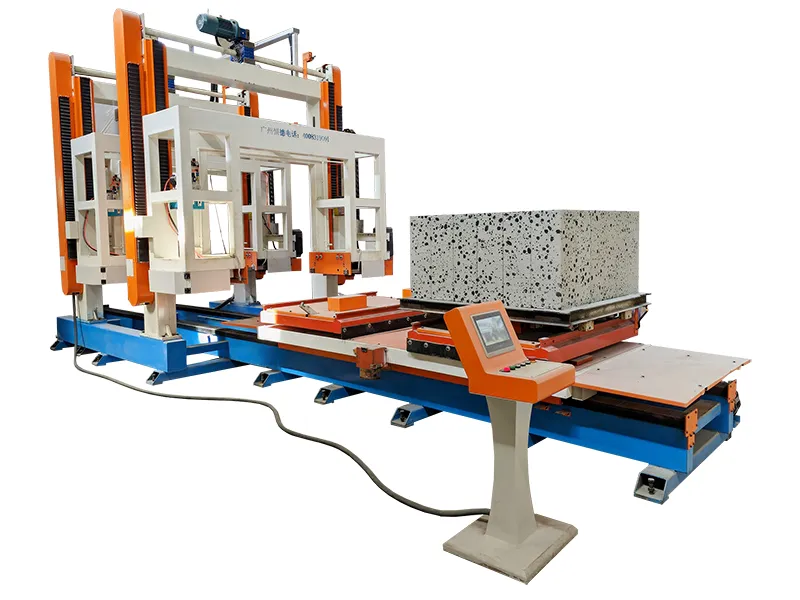

Double-track gantry vertical concrete cutter

Double-track gantry vertical concrete cutter -

Screw air compressor

Screw air compressor -

Screw feeder

Screw feeder -

Concrete block mould

Concrete block mould -

Concrete block grab / lifter

Concrete block grab / lifter -

Belt conveyor

Belt conveyor -

PLC control console

PLC control console -

Concrete block pre-cutter

Concrete block pre-cutter -

Water dosing system

Water dosing system -

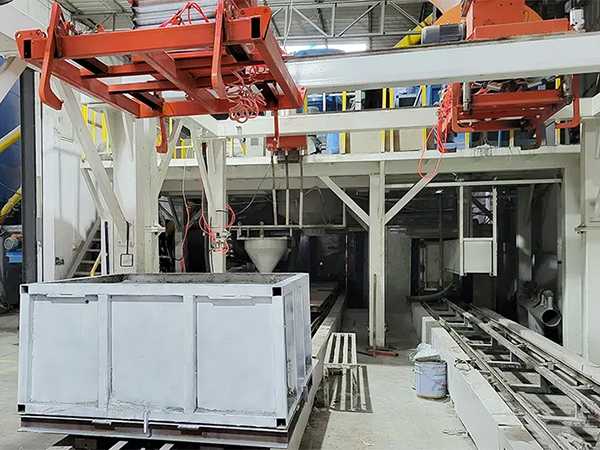

Demoulding crane

Demoulding crane -

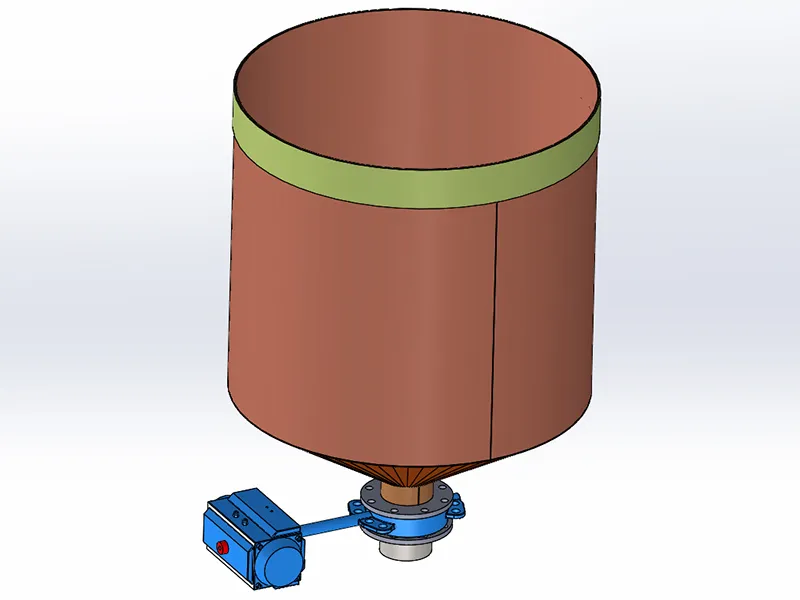

Foam generator

Foam generator -

Remote control module

Remote control module -

Horizontal shaft mixer

Horizontal shaft mixer -

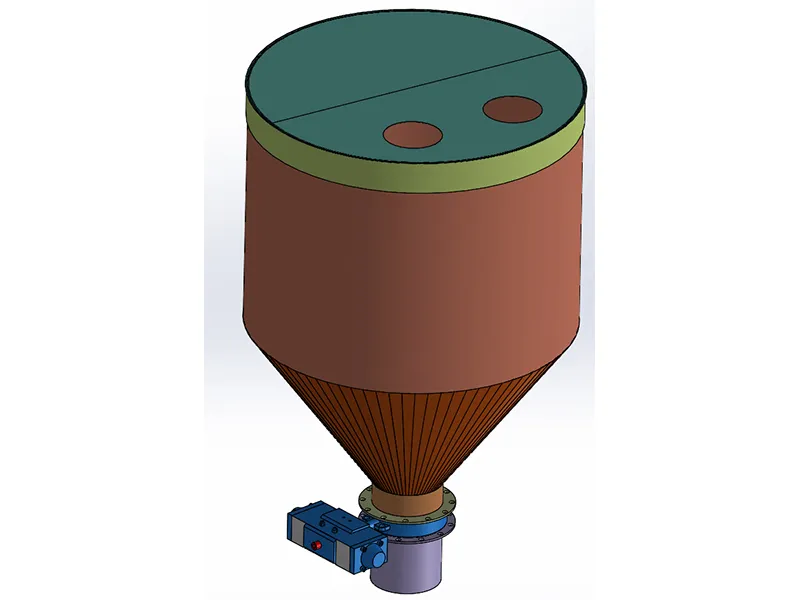

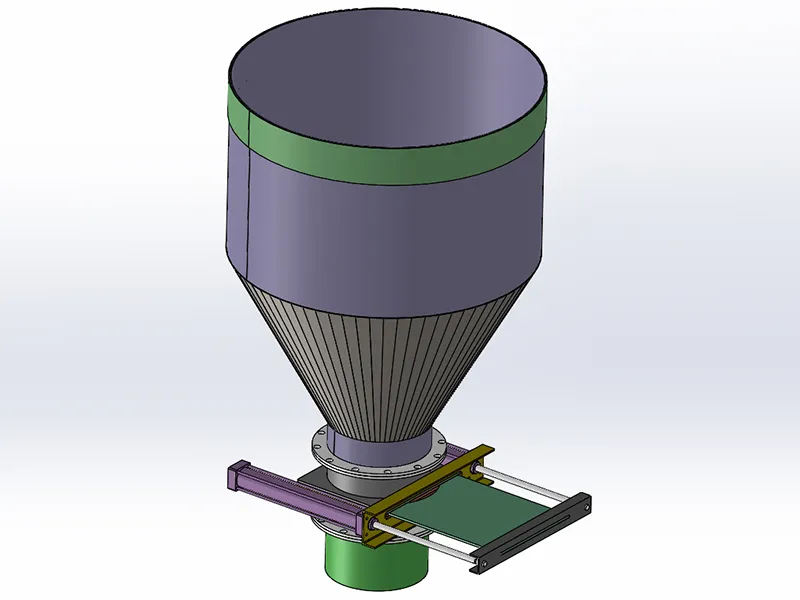

Dosing hopper

Dosing hopper

| Configuration | Model | Dimensions (mm) | Power per unit (kW) | Total power (kW) | Quantity of machine |

| Screw feeder | HDSL | 8000×350×1100 | 11 | 22 | 2 |

| Belt conveyor | HDPDA | 9000×800×800 | 2.2 | 2.2 | 1 |

| Powder dosing and weighing system | HDFL | D1310×H1950 | 0.55 | 0.55 | 1 |

| Dosing hopper | HDSS | D1000×1500 | 0.55 | 0.55 | 1 |

| Water dosing system | HDSL | D1100×H1140 | 0.55 | 0.55 | 1 |

| Foam generator | HDKWF1 | 1150×750×1140 | 7.5 | 7.5 | 1 |

| Screw air compressor | HDKY | L1500×W500×H2000 (air storage tank 0.8m³×1) | 15 | 15 | 1 |

| Aggregates mixing & dosing station | 6000×6400×2600 | 1 | |||

| Horizontal shaft mixer | EPSJB | 2000×1300×1400 | 22 | 22 | 1 |

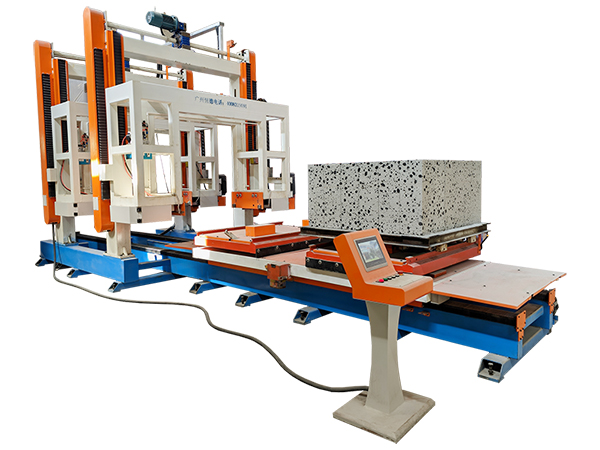

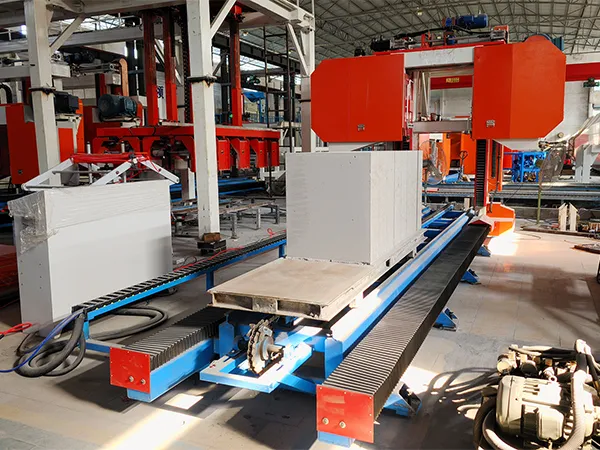

| Double-track gantry vertical concrete cutter | HDSHM1 | 6650×3300×3650 (equipped with high-precision rotary cutting system (suitable for 600mm-high blocks)) | 20.9 | 20.9 | 1 |

| Concrete block pre-cutter | HDOSD1 | 3000×1000×2100 (supplied with power cable) | 22 | 22 | 1 |

| Demoulding crane | HDAS | 3700×1600×3700 | 3.2 | 3.2 | 1 |

| Lifting & stacking machine | HDDB | 4800×2900×4700 | 11.5 | 11.5 | 1 |

| Concrete block grab / lifter | HDYUK | 2200×1200×4200 | 7.5 | 7.5 | 1 |

| Transfer cart | HDBD2 | 1800×1080×400 | 3 | 15 | 5 |

| Demoulding line | HDZD | 6000×1080×470 | 2.2 | 2.2 | 1 |

| Mould return line | HDZD | 6000×1080×470 | 1.5 | 1.5 | 1 |

| Mould pouring line | HDZD | 6000×1080×470 | 1.5 | 1.5 | 1 |

| Automatic feeding line | HDZD | 4m×1.1m | 0.3 | 0.6 | 2 |

| Automatic dischargin line | HDZD | 4m×1.1m | 0.3 | 0.6 | 2 |

| PLC control console | HDKZ1 | 1300×1100×400 | 1 | ||

| Foam generator control panel | HDCBD1 | 700×500×400 | 1 | ||

| Remote control module (enables data import and remote control functionality) | HDYC-001 | 200×150×60 | 1 | ||

| Concrete block mould | HDCM1 | 1220×1220×630 (whole set) | 100 |

- Extensive project experience: our company has undertaken over a hundred construction projects both domestically and internationally.

- Leading technological advantage: we established technical collaborations with German LUCA, German KENA, British CDS, and British TAMCK.

- Comprehensive solutions: We integrate research and development, design, production, and sales to offer turnkey solutions.

- Largest wall panel cutting system: We have developed the world's largest wall panel cutting system, capable of cutting 6-8 cubic meters in a single operation.